About Us

- TOP

-

About Us

Total Manufacture of Automobile Parts from Prototype to Mass Production

We specialize in manufacturing of parts that play a significant role in safety of automobiles including injectors and injector pumps for fuel injection systems, small motors such as power window motors, and sensors such as pressure sensors.

We are able to continue receiving orders from major corporations primarily because of our reliable technical capabilities. We also take pride in the fact that we are highly evaluated for our manufacturing skills.

Business

Engineering Dept.

The Engineering Dept. handles all processes from manufacturing of prototypes to mass production of parts to be sold on in the market.

This department facilitates the shift from prototype to mass production.

○Prototype

We not only finish products to match drawings precisely; we make prototypes while studying all possible issues to ensure smooth transition to mass production.

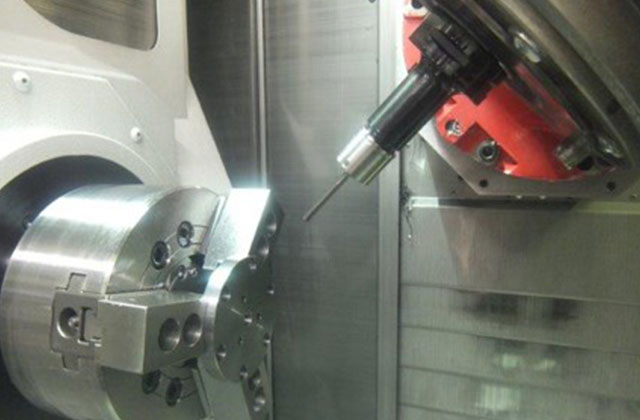

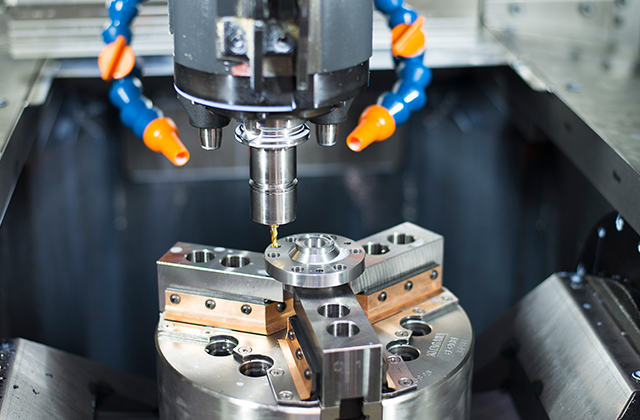

■Equipped with cutting edge IT technology and equipment to handle the customers’ needs

We machine parts, precise to the micro unit by front/rear phasing and simultaneous handling of multiple processes, managing precision altogether with CAD and CAM.

In particular, we employ optical copy grinding lathes for providing a precise finish for products cut in complex shapes.

○Design

We conduct process design especially for precision cutting and machining taking into account equipment/apparatus, machine tools, cutting tools and measurement apparatus required based on it to configure the optimal production system for machining each part.

We are not bound to any particular technology so we can adjust flexibly to use the best equipment to manufacture parts for our customers.

Test/Inspection and Quality Assurance Dept.

We have our most experienced technicians perform testing and inspection using cutting edge measurement devices for all processes for parts obtained from outsource contractors as well as the parts we make ourselves.

-

Tension Tester

-

Emission Analysis Device

-

3D Measuring Machine