Our Mission

- TOP

-

Our Mission

The cutting edge of our company doesn't erode - we stay sharp and always reamain committed to improvement.

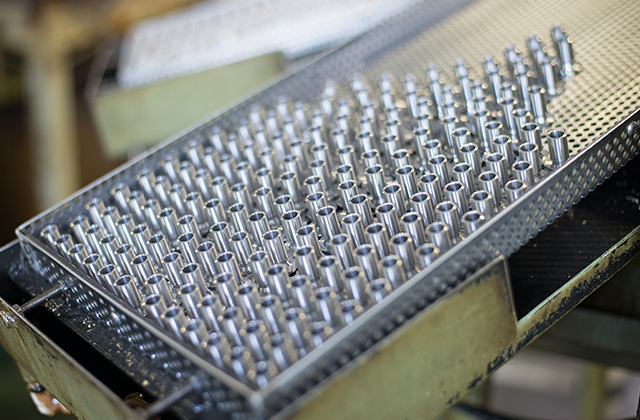

Our fuel injection pumps and ejectors for automobile engines that we handle are important parts related to safety and sense of security. If either of these breaks down, the automobile will cease to function; they are essential for the environment. For example, if there is a single defective product among a million units, it is the only one that matters to the passengers of the vehicle involved. With the awareness that we are making parts that relate to safety of vehicles on which lives depend, we do our utmost to prevent defective products from being produced. We have polished our skills for cutting iron, so we make sure we do not erode. We plan to keep manufacturing products based on this concept.

Yutaka Industry pursues “smart factory production” that combines superior quality with smartness.

What is a “smart factory”?

“Friendliness to people” is required to reduce stress on the human body by creating an environment where each person can exhibit their talent while concentrating on machining that does not place unreasonable demand on workers in an environment where each employee can enjoy the challenge of working with advanced technologies on a daily basis; “smartness” refers to accumulation of data and putting AI to practical use.

Model of Smart Factory, Anjo No. 6 Factory

Completed in September 2018, the No. 6 factory was built as a model smart factory. When designing, people from the various departments of the company were gathered and asked for ideas. Among the ideas used by people working at the site were one-way roads for trucks to promote safety and efficiency. While there are many factories that employ “technical smartness,” our factory also pursues “friendliness to workers.”

Yutaka Industry has six buildings at Anjo and two buildings at the Gifu to realize manufacture of automobile parts of the highest quality.