Our Strengths

- TOP

-

Our Strengths

In addition, by performing one-stop services from prototype to mass production, quality and production management are maintained at high levels, with optimal efficiency.

01. Quick Prototype Production

Prototype in super-short period of time We produce the best possible prototype from the customer’s drawing according to the desired specifications, deadline and cost.

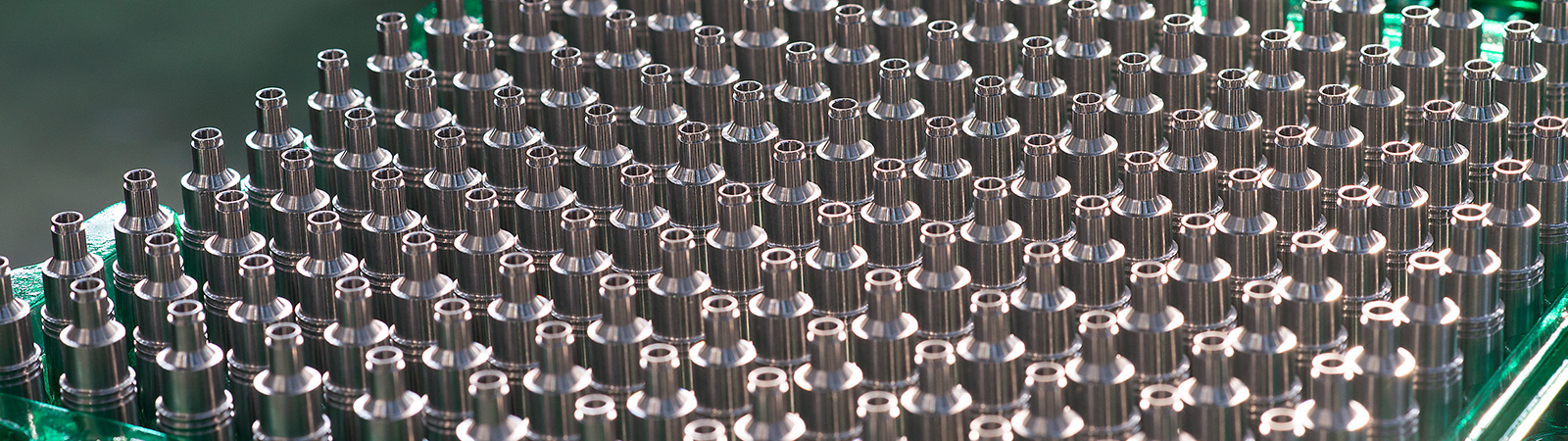

We handle all processes from manufacturing to finish in-house to enable the quickest delivery of goods possible.

We can also suggest the best way to produce prototypes according to product application and objective.

Yutaka Industry produces prototypes, with a market launch in consideration, and can adjust to shift to mass production, ensuring the quality of the product.

Creating prototypes with the same quality, materials and function capability as in mass production are also possible.

The initial cost is reduced due to in-house production. We can reduce risk by creating and evaluating prototypes of the same materials as your manufactured parts. Improve product development efficiency through quick delivery of prototypes.

02. One-Stop Process

One-stop support from production and manufacturing of prototypes molds to mass production lines, including material procurement to processing.

We listen to all the customer’s requirements so we can manage and produce products with optimal quality at lowest cost by incorporating the information into our manufacturing.

All mold designers, prototype manufacturing and process engineering staff work together on improvements in the mass production process to use feedback to optimize mass production factories and make them more efficient with better quality control.

- By optimizing various conditions such as material, equipment, quantity, delivery date, cost, etc. through an in-house integrated system, we made it possible to respond flexibly from the prototype stage to the start of mass production.

- The one-stop process enables manufacturing that is highly competitive in terms of cost.

Order Procedure

-

01

ConsultationBefore you give up, contact us.

Our job is to lead to the realization of the strict demands of our customers with the technical capabilities and know-how we have built over the years. Please feel free to contact us first. -

02

Place orderWe offer hearing process to pay close attention to your request

-

03

Select materials and machineryBuild the optimal production system

We put together the optimal production system for each machined part taking into account equipment/machinery, machine tools, cutting tools and measuring instruments. -

04

MachiningOne-stop support for high-precision parts

With over fifty years of experience, our cutting and machining technologies, you can count on us to provide you with precision finished products. -

05

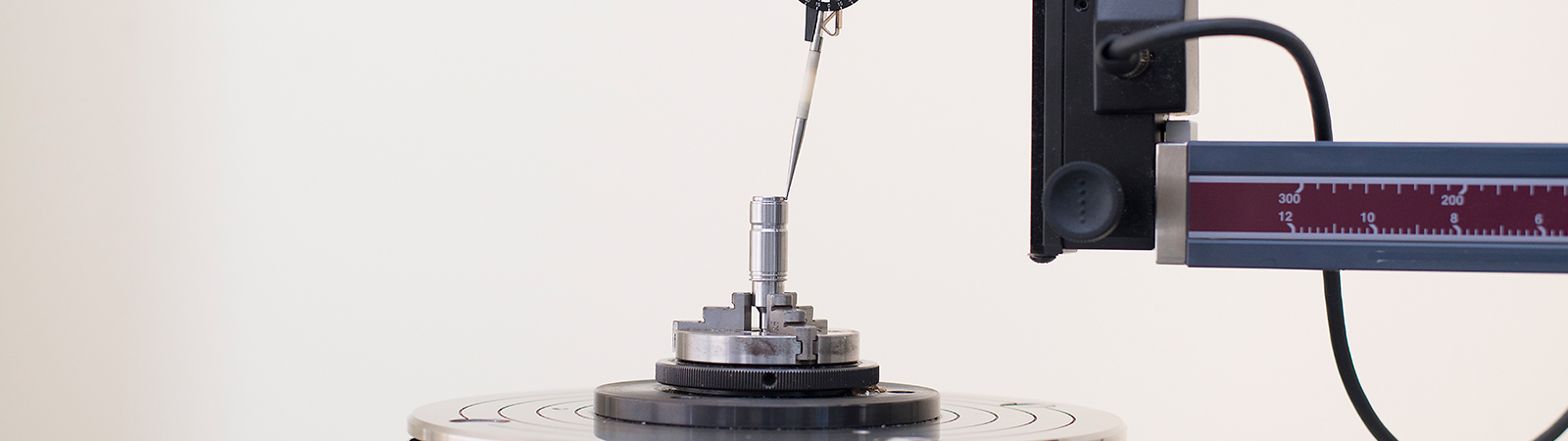

TestingDelivery of reliable finished parts using cutting edge measurement instruments

Beginning with CNC 3D measuring machines, we test and inspect our products to ensure high-precision machining. Products are checked to make sure they accurately match specifications and drawings. -

06

Delivery

03. High Precision Quality Aiming for difference of ≥7 microns

We continue to maintain the highest quality in Japan with various know-hows, such as the technology that controls the difference of 3.5 microns on one side, from our experience accumulated over the course of half a century. Please contact us for prototypes with specific dimensions.

The Uniqueness of Yutaka

In addition to processing parts in micro units, we have developed high-performance equipment in-house!

Our Uniqueness

In addition to processing parts in micro units, we have developed high-performance equipment in-house!

Utilizing the needs and wisdom from the production site, we design and manufacture equipment machinery dedicated to parts processing in order to streamline and automate.

【Original Equipment】

-

Robot conveyor palletizer

-

Parts feeder

-

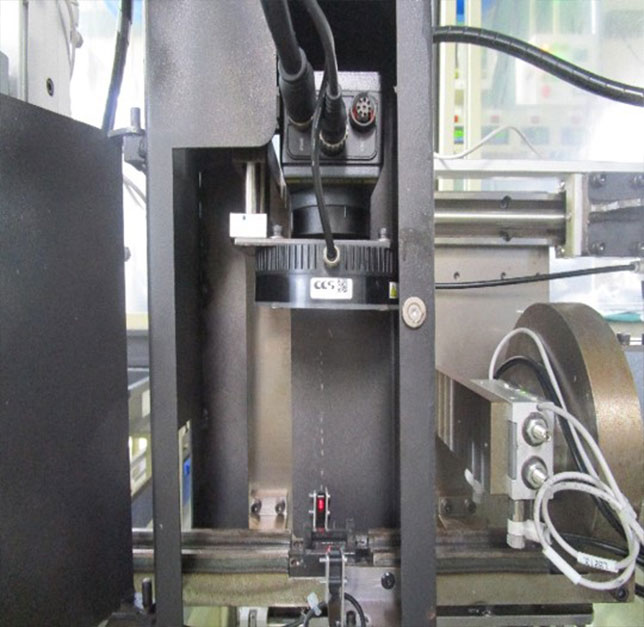

Packing machine with image processing

【List of Original Equipment】

Drills, dedicated tapping machines, transfer machines, automatic packaging machines, automatic testing/inspection equipment, etc.

Labor-saving, automatic testing/inspection equipment employing unique ideas is used at production sites to test and inspect quality of parts after machining.

Our Uniqueness

Possible Environment

We at Yutaka Industry aim to "continue to provide good products at low cost”. We are particular about being able to make everything possible. We don't take the word “continue” lightly, rather it is our mission to continuously offer good quality naturally. We take in consideration on-site feedback to create an environment where workers can continue to work independently without placing a burden on others.